Enviro-Safe® EBC brings with its use an ability to allow the new form of the contaminant to absorb usable nutrients so that the environment can decompose (digest) the new form and biodegrade it into the environment.

DESCRIPTION:

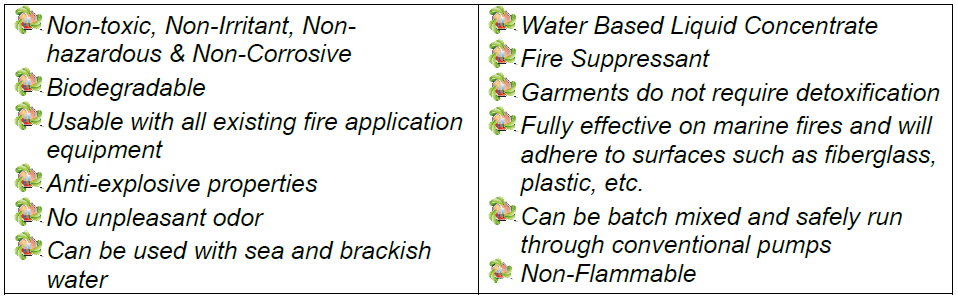

- CONCENTRATE (A High Kinetic Active Foamer)

- USAGE: 6% or as required

- NON-FLAMMABLE

Enviro-Safe® EBC employ a combination of multiple oil slick suppression and barrier production environments that deliver deep penetration to the oily surface capable of dispersing the oil spill hazard quickly without emulsifying the oil and thus creating a homogeneous aqueous mixture that allows its content to disperse throughout the environment so that biodegradation can take place. As an additional benefit, Enviro-Safe® EBC brings with its use an ability to allow the new form of the contaminant to absorb usable nutrients so that the environment can decompose (digest) the new form and biodegrade it into the environment.

ADVANTAGES:

ENVIRONMENTAL & TOXICOLOGY TESTING

Enviro-Safe® EBC was independently tested and found to be non-hazardous to fish according to OSPAR Commission 2006 Part B Protocol for a fish acute toxicity test, OECD guideline 306, ‘Biodegradability in Seawater- Closed Bottle Method’ (OECD1992), ISO 14669 (1999) Water Quality – Determination of acute lethal toxicity to marine copepods (Copepoda; Crustacea ) ISO 5667-16 (1998) Water Quality Sampling – Guidance on biotesting of samples, and ISO 10253 2006 Water quality and Marine algal growth inhibition test with Skeletonema costatum Study. The mixture is not an eye or skin irritant and is non-toxic when tested according to the FHSA protocols. It is judged to pose no chronic health hazard. Under European standards (OECD 301 part A-F), ERCD’s meet “green” qualification. The ERCDs require no special labeling or chronic health hazard warning statements and are in compliance with FHSA regulations, 16 CFR 1500 and California Proposition 65.

- SPECIFICATION/APPLICATION

Enviro-Safe® EBC is a water thin concentrate, fully miscible in water for premixing capacity ideal for systems and manual application (ERCDs Can Be Batch Mixed And Also Proportioned).

APPLICATIONS:

ENVIRO-SAFE® EBC OIL DISPERSING PROPERTIES CAN BE APPLIED TO ANY OIL SPILL WHETHER ON LAND, GARMENTS, EQUIPMENT, OR ON WATER SURFACES. NO SPECIFIC VOLUMES ARE DETERMINED OR RECOMMENDED BY THE MANUFACTURER. USER SHALL DETERMINE BY PRACTICAL EXPERIENCE SUCH VOLUMES NECESSARY TO DISPERSE THE REQUIRED TASK.

- IMPORTANT NOTICE TO PURCHASER: ANY ALTERATION TO THE ORIGINAL FORMULA, EXCEPT FOR ITS INTENDED END USE, SHALL VOID ANY AND ALL WARRANTIES OF PRODUCT. The following is made in lieu of all warranties, expressed or implied, including the implied warranties of merchantability and fitness for purpose: Sellers and manufacturer’s only obligations shall be to replace such quantity of the product proved to be defective. Before using, user shall determine the suitability of the product for its intended use, and user will assume all risk and liability whatsoever in connection therewith. NEITHER SELLER NOR MANUFACTURER SHALL BE LIABLE IN TORT OR IN CONTRACT FOR ANY LOSS OR DAMAGE DIRECT, INCIDENTAL, OR CONSEQUENTIAL, ARISING OUT OF THE USE OF OR THE INABILITY TO USE THE PRODUCT.

HOW DO WE COMPARE WITH THE CURRENTLY IN USE PRODUCT

What is Corexit?

Corexit is a line of oil dispersants or solvents, originally developed by Exxon and now manufactured by Nalco Holding Company (NHC) of Naperville, IL. Interestingly, NHC is associated with Exxon and British Petroleum (BP) — the latter is the same company that insists on using Corexit.

Oil dispersant is basically a detergent, like your dishwashing detergent. It disperses or breaks up the oil film into small droplets that intermix with seawater.

There are at least four different formulations of Corexit:

- Corexit EC 7664A

- Corexit EC 9500A (aka Corexit 9500)

- Corexit 9527A

- Corexit EC 9580A

Corexit EC9500A is mainly comprised of hydro treated light petroleum distillates, propylene glycol, and a proprietary organic sulfonic acid salt. Propylene glycol is a chemical commonly used as a solvent or moisturizer in pharmaceuticals and cosmetics. An organic sulfonic acid salt is a synthetic chemical detergent, such as that used in laundry detergents, which act as a surfactant to emulsify oil and allow its dispersion into water.

A variant of Corexit was used in the 1989 Exxon Valdez disaster in Alaska. In the present Deepwater Horizon oil spill, BP is using unprecedentedly large quantities of Corexit EC9500A and Corexit EC9527A, applying 800,000 gallons total, but more accurate estimates run as high as 1,000,000 gallons underwater.

Is Corexit Effective?

Corexit 9500 was 54.7% effective and Corexit EC9527A was 63.4% effective in handling Louisiana crude oil. Corexit is not very efficient oil dispersant; there are others that are better. (More below)

Is Corexit Safe to Use?

The short answer is “No!” Corexit is highly toxic to humans as well as marine life.

The federal Environmental Protection Agency (EPA) has identified the 2-butoxyethanol in Corexit to be a causal agent in the health problems experienced by cleanup workers after the 1989 Exxon Valdez oil spill of respiratory, nervous system, liver, kidney and blood disorders.

According to the Material Safety Data Sheet (MSDS), Corexit 9500‘s “potential human hazard is: High.” It can cause central nervous system depression; nausea; unconsciousness; liver, kidney damage; and red blood cell hemolysis with repeated or prolonged exposure through inhalation or ingestion.

Here is what the MSDS for Corexit EC9500A says about Accidental Release Measures: PERSONAL PRECAUTIONS: Restrict access to area as appropriate until clean-up operations are complete. Ensure clean up is conducted by trained personnel only. Ventilate spill area if possible.

Do not touch spilled material. Remove sources of ignition.

Stop or reduce any leaks if it is safe to do so. Have emergency equipment (for fires, spills, leaks, etc.) readily available. Use personal protective equipment recommended in Section 8 (Exposure Controls/Personal Protection). Notify appropriate government, occupational health and safety and environmental authorities.

RESPIRATORY PROTECTION: If significant mists, vapors or aerosols are generated an approved respirator is recommended. An organic vapor cartridge with dust/mist prefilter or supplied air may be used. In event of emergency or planned entry into unknown concentrations a positive pressure, full-face piece SCBA should be used. If respiratory protection is required, institute a complete respiratory protection program including selection, fit testing, training, maintenance, and inspection.

HAND PROTECTION: Nitrile gloves, Viton# gloves, Polyvinyl alcohol gloves SKIN PROTECTION: Wear impervious apron and boots.

EYE PROTECTION: Wear chemical splash goggles.

HYGIENE RECOMMENDATIONS: Keep an eye wash fountain available. Keep a safety shower available. If clothing is contaminated, remove clothing and thoroughly wash the affected area.

Launder contaminated clothing before reuse.

On May 19, 2010 the EPA gave BP 24 hours to choose less toxic alternatives to Corexit, selected from the list of EPA-approved dispersants on the National Contingency Plan Product Schedule. BP was to begin applying the less toxic dispersants within 72 hours of EPA approval of their choices, but BP refused to change from Corexit, citing safety and availability concerns with alternatives.

According to the EPA, Corexit is more toxic than dispersants made by several competitors and less effective in handling southern Louisiana crude. Not only is Corexit toxic to human and marine life, it helps keep spilled oil submerged. The quantities used in the Gulf will create unprecedented underwater damage to organisms.