A Carbon Capture, Storage, and Utilization System Affording a New Revenue Source to the Petrochemical Industry

BACKGROUND

FireStopper® International Limited (FireStopper®) is a transnational Registered Company and is the developer of the world’s most advanced and uniquely powerful firefighting, anti-explosion, environmental remediation, burn injury medical application, lubricant and other unique applications; “A Proprietary Technology,” which is fully & reliably effective against all flammables. This unparallel technology is strictly protected under the Uniform Trade Secret Act (“UTSA”) Cal. Civ. Code Sec. 3426, Common law, Business and Profession §17200, and all other applicable U.S. and International statutes to prevent unlawful acts. Additionally, this technology, which also has environmental remediation and other supporting applications, is classified as an “Exclusive and Closely Held Intellectual Property.”

A product of “Quantum Chemistry,” this Technology not only offers unprecedented extinguishment of flammable events, but its specialized properties against flammable materials ensure usability, safety, and reliability in any physical environment. The FireStopper® Products are the only products in the industry certified for human use and exposure, with safety measures extending to animal life in both marine and onshore settings. Moreover FireStopper® produces products suitable for all temperature conditions and are non-aggressive to materials.

In order to achieve the exceptional standing, FireStopper® devoted over 30-years focusing on intensive research and development as well as market research. This dedication has led to FireStopper® receiving top-tier global testing and certifications that far surpass those of its competitors. These certifications are a testament to FireStopper®’s exceptional performance in fire ratings, usage, and environmental standards, all of which have been awarded by reputable testing and certification facilities worldwide.

The innovative Technology mentioned earlier has revolutionized the fire safety industry by offering the only “all fire class” effective and “anti-explosive” products available. These products not only ensure safety but also provide significant economic advantages to end-users, surpassing all competition. By meeting and exceeding the most stringent market requirements, the FireStopper® “Brand” stands out as the top provider of fire safety products globally. FireStopper® remains dedicated to maintaining its technological leadership in the industry.

“When the Need for Change is Compelled, FireStopper® Responds by Demonstrating its Ability to Deliver to the Demand”

Our commitment is to introduce top-notch innovations whenever and wherever changes are necessary to exceed expectations, ensure and uphold the highest level of safety for the first responders, the beneficiaries of the fire service, the general public, the environment, and the Planet. FireStopper® acknowledges the importance of meeting the requirements of the People, Industry, and Government by developing and providing a comprehensive infrastructure hardware array that effectively addresses the longstanding unresolved issues abundant with firefighting.

Massive water damage, destruction by fire, and the contamination of the environment; all at the cost to the People paid through taxation and the ever-growing costs of Insurance.

FireStopper® Products are exclusively Marketed, Distributed, and managed Globally through its subsidiary FireStopper® Global, Inc.; for questions and in-depth information, please visit us at: firestopperglobal.com and firefightingcatalyst.org

OVERVIEW:

The FireStopper® FFC Technology has demonstrated its capability to support a diverse range of applications, ensuring reliability and exceptional effectiveness tailored to each specific use. It offers economic benefits in both usage and application costs, while prioritizing safety for humans, animals, and the environment. Furthermore, the versatility of FireStopper® Products in various environmental conditions is a defining characteristic.

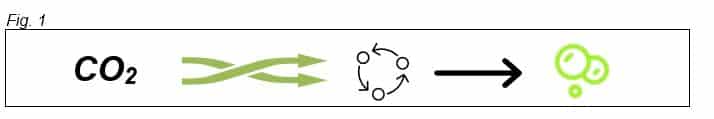

Presented in this white paper, The FireStopper® FFC Technology provides an innovative and previously unavailable method for effectively minimizing CO2 emissions typically generated by the Petrochemical Industry during exploration and refining activities. For instance, we can examine recent statistics released in 2021:

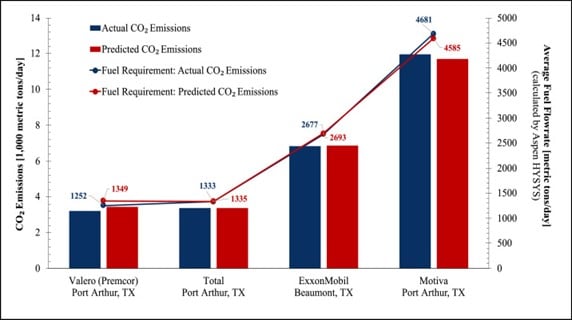

According to the Chemical Engineering Journal Advances, oil refineries are industrial complexes that upgrade crude oil to fuels and chemical products that are of high monetary value. However, due to the nature of these processes, refineries also produce significant amounts of CO2 emissions. According to statistics, the refining sector produced an estimated 478,000 metric tons of CO2 every year, second only to power plants as a producer in CO2 emissions. Hence, the refining sector would serve as a viable candidate for deploying CO2 capture infrastructure to abate CO2 emissions. In addition to the large CO2 emissions, refineries of certain regions of the United State (i.e., Southeast Texas, USA) are well suited for Carbon Capture and Storage (CCS) operations due to unique geological features that would allow for permanent CO2 capture and recycling. The Southeast Texas region is in close proximity to the shallow waters of the Gulf of Mexico where several off-shore depleted oil reserves are present. This proximity provides a distinct opportunity for the refineries of this region to permanently fix CO2 within the sub geological layers, which then can be used to supply algae operations.

Table 1:

Without taking in consideration the fact that the Planet cannot survive without CO2, which is a key ingredient for maintaining the necessary balance to produce breathable air in our atmosphere. This necessary gas is key in providing the environment with the necessary abundance of CO2 for vegetation to survive on our planet, which plants require to produce the oxygen the atmosphere needs to supply the breathable air all species living on the phase of this Planet require for life, this fact is indisputable.

Nonetheless, FireStopper® is poised to capture, store, recycle for reuse, and enhance Industry’s capacity to add or enlarge the production of biofuel thus increasing profitability to the enterprise and by extension, enhancing the environment with additional renewable fuel source; thereby, establishing a “win-win” scenario for the Planet and its inhabitants.

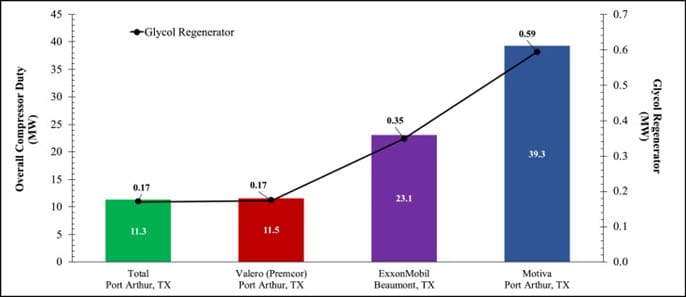

Discussion: Under the currently used technology, the power requirements of the CO2 compression and dehydration units for the four selected refineries is shown in Fig. 7. The column duty for the glycol regenerator column was calculated by adding the absolute values of the reboiler duty and the condenser duty. As expected, the power required for CO2 compression was found to depend on the amount of CO2 emissions from the refineries (assuming that all the CO2 emissions are available for capture and 90% of the CO2 is recovered by the capture unit and used for compression). The order of the compression duty for the refineries is the same as that of the predicted CO2 emissions (i.e., Total < Valero Premcor < ExxonMobil < Motiva).

Table2:

With the implementation of the FireStopper®’s EnviroSafeÒ Bio-SphereTM Product, for CO2 capture and recycling, no additional energy is required to secure the CO2 byproduct as the above example presents. This is just one of the many advantages the FireStopper® innovations offer the World to save life, both Human & Animal, while saving the Planet’s biosphere.

THE NOVEL SOLUTION:

The binary solution offered by FireStopper® is simple and self-sufficient. The process requires 2 components:

- The creation of an adjacent microalgae farm to the petrochemical Industry

- Reengineering the method presently employed to sequester & dispose of the captured CO2.

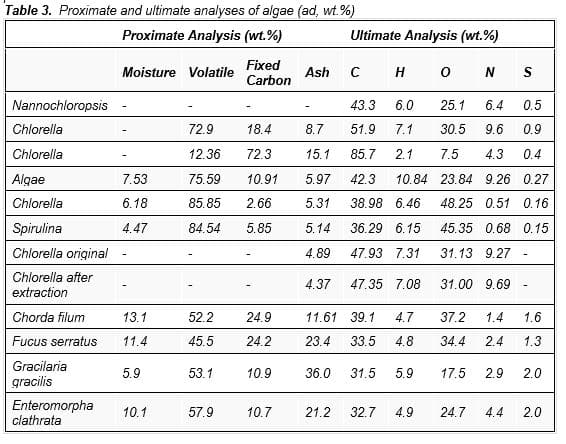

The significance of developing algae as a remedy for this byproduct is considerable. Algae is recognized as a promising source of renewable fuel due to its rapid growth and capacity to accumulate lipids. Research has demonstrated both the potential of this energy source, and the inherent challenges associated with using organic algae as fuel.

Table 3 shows the results of the Proximate and ultimate analysis of various types of algae.

THE SIMPLICITY OF THE FireStopper® SYSTEM

The FireStopper® approach offers an unparalleled solution for end-users and industries, enabling them to achieve a fully recyclable, safe, and cost-effective method to address perceived challenges while simultaneously complying with regulatory requirements and enhancing company profitability. Any CO2 sequestration system can be adapted to integrate seamlessly with the proposed FireStopper® System.

FireStopper® invites all interested parties to contact us directly at: info@firestopperus.com for more specific and on point information.