Introducing A Novel Approach to Nuclear Plant Safety

This Technical White Paper explains FireStopper®’s unique technology that offers worldwide implications to Improve Nuclear Plant Safety to levels of safety and protection never believed possible. The paper has detailed and supporting data that substantiates claims that the application of FireStopper® technology can readily provide safety and protection against Nuclear Plant accidents. Included is a discussion on Nuclear Plant Safety solution for nuclear waste disposal.

Preface

FireStopper International Limited, a transnational Registered Company, is the developer of the most advanced and powerful firefighting and anti-explosion technology in the “World”. It devoted the first 25-years of its existence to R&D and the recipient of subsequent stand alone testing results in ratings and certifications by the most recognized and respected third-party testing and listing facilities in the world.

Moreover, this unique Technology has rendered the only available all fire class effective and anti- explosive products, which are non-toxic, non-irritant, environmentally safe and non-hazardous per the most demanding environmental and life exposure testing over all other existing and available products in the explosion, fire and safety channel of business.

In the explosion amelioration technology channel, FireStopper® branded anti explosion systems exclusively deploy EXP FFC and in the handheld portable fire extinguishers PFE-FR FFC is exclusive to FireStopper® trademarked systems. The FireStopper® FFC Technology (Fire Fighting Catalyst) produce the only true environmentally safe liquid formulas in the world.

In addition, EXP FFC is recognized as being the only product capable of suppressing hydrogen/ methane explosive environments in over 20-years of search. This breakthrough discovery became apparent during its initial demonstrative testing at Gexcon1, AS Norway.

PFE-FR FFC is additionally recognized as the only all fire class and subclass effective liquid suppressant and due its freeze resistance of -73.3ºC (-100º F) this line of portable extinguishers can be deployed in all environments in the planet.

For mass application in the advent of fire, FireStopper® XL”PLUS FFC is the recommended product of choice where high life, environment and infrastructure are at risk.

Having proven the former statement through the outstanding results of the products testing, rating, and certifications thus received, FireStopper®, in tandem with its novel firefighting and anti- explosion products (the “software”), developed the most durable and reliable supporting hardware and detection systems available today, which also meet and exceed the relative standards used to certify said product lines.

With the advent of this technological breakthrough, FireStopper® has expanded this technology into the Nuclear Energy channel by developing products that advance safety and protection not yet available. FireStopper® can now provide Government, Industry, and by way of innovation, the consumer with a never before wider dimension of safety and protection.

FireStopper® through its extremely versatile and novel FFC/EnviroSafe® Technology has developed a system of applications that can ameliorate by maintenance, suppression and elimination of the devastating effects brought about by imminent disaster due to the above mentioned potential catastrophic failure.

Notwithstanding the above, the FireStopper® lines of products reach across the full spectrum of safety application including environmental remediation post spills both onshore and offshore. In the International arena, the FireStopper® brand is the recipient of the highest certifications in all categories of Governmental requirements to market such as defined below:

Nuclear Energy Electricity Generating Facilities

FireStopper® Products By Application:

EnviroSafe® XPC & EnviroSafe® XPK2

(The above products are designed for spent nuclear rod submersion and maintenance)

Anti-Explosion:

FireStopper® EXP FFC

(This liquid media is designed to deliver fire and explosion amelioration/suppression exclusively through FireStopper® Designed Anti-Explosion SystemsTM)

Initial Stage Testing – Gexcon, AS (Norway)

Handheld Portable Fire Extinguishers:

(The only all fire class & sub-classes effective handheld extinguishers in the world – Full catalog available upon request)

Certifications/Approvals:

ANSI/UL711, ULC – Southwest Research Institute (San Antonio, TX) Defense Logistics Agency (DLA) US Gov. NSN Approval #s’

EN3-7; EN3-83 – MPA, Dresden (Germany) CE4 – DNV

Firefighting Foam Concentrate Product & Certifications:

FireStopper® XL “PLUS” FFC

EN1568 – MPA Dresden ICAO – CNPP (France)

IMO – MPA Dresden, Lloyds Registry, DNV, MED CE

Environmental Testing:

NAMSA, USA

Associated Laboratories, CA USA Environmental Medicine, Inc., USA OPUS, Ltd., UK

Executive Summary

Every new technology encounters barriers to new product entry. Often times these barriers are based on myth, inaccurate facts that have been presented in the media or by established competitors and some times the barriers are based on real world experience of customers using purported similar technologies, which in fact are not. In this instant presentation, a truly new technology is here that addresses the need for protection in a different way. In all cases, it is incumbent upon the vendor to educate the end user, technical personnel, analysts, and the press about the technology or a new approach to solving continuing problems in the industry.

In the course of generating electricity, nuclear plants create amounts of highly radioactive waste in the form of spent nuclear fuel, which constitutes a significant hazard to human safety if not properly stored and disposed. Because of the radioactivity and extreme longevity of spent nuclear fuel (half- life: approx. 156,000-yers) its management is a major policy challenge for virtually every country in the world that generates nuclear power (According to the National Academy of Sciences National Research Council, 1990, the best way to dispose of nuclear waste is in a geologic repository). This is also the common conclusion of all nations with nuclear power plants.

After nuclear fuel has been used for five to six years to furnish the power to produce electricity, the spent (or used) fuel, which is still highly radioactive, must be stored on the reactor site until it can be moved to a geological disposal site (should it be available). For example, the disposal site selected in the United States was Yucca Mountain, located in a remote desert region of the Nevada Nuclear Weapons Test Site. However, after 20 years of study, a cost of $10 billion, and the submission of a licensing application to the Nuclear Regulatory Commission (NRC), which was nearing completion of its review, President Obama directed the U.S. Department of Energy (DOE), the responsible federal agency, to cancel the project. That decision is being appealed in the courts, and the outcome is still not clear.

|

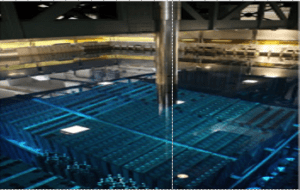

Every nuclear energy plant must store its spent rods onsite in massive concrete pools (generally with 6-ft thick walls) large enough to submerge said rods in minimum of 20-ft of water (usually these pools are 40-ft deep). These pools must maintain constant recycling of water in order to regulate and maintain the temperature within the safety margin. Unfortunately, this method is no longer viable; the many events such as Chernobyl, Fukushima, 3- mile Island and others beg for active research for additional safety measures to be implemented. |

In the past, heavy water (H3O) was employed to keep and maintain spent rods in the storage pool; this did not prove to be either safe or economic. Saltwater became the next replacement, which generally is pumped to supply the pools at present. This current method presents various, now unacceptable, possibilities for catastrophic failure, e.g.:

- Natural events such as:

- Earthquake

- Weather born disasters

- Systemic failures

- National emergencies

- Intentionally acts

- Among other potential events

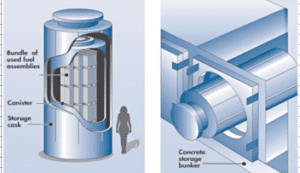

Dry Storage

By the end of 2011, the United States commercial nuclear waste inventory had reached approximately 65,000 metric tons of heavy metal (MTHM). This represents about 224,000 fuel assemblies. Roughly 50,000 MTHM are held in spent fuel pools. The remaining 15,000 MTHM have been placed in casks that are collectively referred to as “dry storage.” Roughly 2,200 MTHM are produced each year by existing nuclear reactors.

|

Spent fuel canisters are filled with inert helium gas to prevent degradation by oxidation. They are then seal welded and placed in concrete cylinders fitted with inner metal liners (which provide radiation shielding) or in separate metal enclosures. Canisters loaded with spent fuel are moved to dry- storage facilities, referred to as independent spent fuel storage installations (ISFSIs) on the utilities’ sites. ISFSIs are large, parking-lot-type concrete pads surrounded by protective fencing and under continuous security surveillance. |

Typical storage casks can be stored in either vertical or horizontal systems (Figures 2 and 3). Cask systems are popular among reactor

operators because of their inherent flexibility. For one thing, they allow for the modular expansion of storage capabilities. For another, licensed “dual- purpose” casks can be used for both storage and transportation of nuclear waste. Some cask vendors have even developed “multiple-purpose containers” they hope will be suitable for storage, transport, and disposal.

What FireStopper® Offers:

In the alternative to the current safety maintenance products and protocols, the newly developed branch of FireStopper®/EnviroSafe® Product Line offer the following:

- Salt/sea water in cooling pool is limited by temperature resistance to heat

- At atmospheric pressure (1013 mbar) is 65 °C (213.17ºF)

- High evaporation environment

- EnviroSafe® XPC & XPK provide temperature resistance to heat at a far greater temperature than sea water

- These proposed products possess both endothermic and exothermic properties

- Produce low evaporation environment

- Salt/sea water provide minimal protection against temperature breach related fire

- FireStopper® XPC & XPK both offer great suppression protection against spontaneous breach by fire

- Subsequent lab testing* will determine the following:

- Product life while deployed

- Direct positive effect on fissionable materials

- Other positive results

- FireStopper® suggests that potential industry users test the products sited above in their facility labs for efficacy and

Conclusion

As a result of political decisions, spent fuel in the United States will have to be stored either at reactor sites or in regional interim storage facilities. Given the political difficulties of finding a state and community willing to host either an interim storage facility or a waste repository, predictions of success or timing cannot be made. Here is what we do know:

- Storage at reactor sites will be necessary for a minimum of 10 more

- According to NRC, spent fuel can be safely stored in dry casks for at least 60 years, and evidence may show that it can be stored for even

- Building an interim storage facility is currently not permitted by law. Therefore, legislative action will be necessary before such a storage facility can be considered.

- Once an interim facility has been identified and licensed, transportation to the site will require considerable additional time and investment.

- Until DOE removes the spent fuel from operating and decommissioned sites, the cost to taxpayers for the government’s failure to build a repository will continue to

- The top priority for ending this costly financial obligation completely is to remove spent fuel from decommissioned sites. The obligation would continue for operating sites, however, until DOE removes all of the spent fuel, as obligated by contracts with utilities.

Facilities throughout the world will encounter similar and possibly worst Governmental scrutiny over this very serious matter. In the meantime, any new or existing nuclear plant should consider new and effective measures to protect the functioning of the plant, the personnel and most important the environment, the general population and the planet.

This is no longer a question of economics; the responsibility lay squarely in the hands of Government and Industry to identify, test and implement novel applicable technology to deliver the most responsible safe environment for this industry.

** FireStopper International Limited does not have access to fissionable materials to test the level of efficacy its newly developed products afford this industry. Therefore, we encourage interested parties to participate in the investigation of important technology. FireStopper® is committed provide limited assistance in this matter to the limits necessary to protect this very valuable trade secret technology.

_______________________________________________________________

1 This Standard refers to hardware durability, reliability and efficacy

2 These products need to be tested by the intended Nuclear Facility since fissionable materials are not readily available

3 This Standard refers to hardware durability, reliability and efficacy

4 This Mark assures manufacturing quality through yearly inspections

=================================================================

Spent Nuclear Rod Storage & Environment – Green Safety Solution

The objective of this document is to spotlight the least known and potentially most destructive danger to our species. Then, to introduce and describe the now available, solution to blocking a Fukushima type disaster from occurring, which by all publicly available information, far exceed the conditions that gave birth to such a disaster.

Preface

FireStopper International Limited**, a transnational Registered Company, is the developer of the most advanced and powerful firefighting and anti-explosion technology in the “World”. It devoted the first 25-years of its existence to R&D and the recipient of subsequent stand alone testing results in ratings and certifications by the most recognized and respected third-party testing and listing facilities in the world.

Moreover, this unique Technology has rendered the only available all fire class effective and anti- explosive products, which are non-toxic, non-irritant, environmentally safe and non-hazardous per the most demanding environmental and life exposure testing over all other existing and available products in the explosion, fire and safety channel of business.

In the explosion amelioration technology channel, FireStopper® branded anti explosion systems exclusively deploy EXP FFC. This FireStopper® FFC (Fire Fighting Catalyst) is an environmentally safe liquid formula (embodying all the safety characteristics of this unique technology) that has garnered the great distinction of being the only product in over 20-years of search for a product capable of suppressing hydrogen/methane explosive environment. This breakthrough discovery became apparent during its initial demonstrative testing at Gexcon, AS Norway.

Having proven the former statement through the outstanding results of the products testing, rating, and certifications thus received, FireStopper®, in tandem with its novel firefighting and anti- explosion products (the “software”), developed the most durable and reliable supporting hardware and detection systems available today, which also meet and exceed the relative standards used to certify said product lines.

With the advent of this technological breakthrough, FireStopper® can now provide Government, Industry, and by way of innovation, the consumer with a never before wider dimension of safety and protection.

Notwithstanding the above, the FireStopper® lines of products reach across the full spectrum of safety application including environmental remediation post spills both onshore and offshore.

This company believes that in its capacity as a innovative manufacturer, that it must deliver equally performing hardware with reliability and durability to complement such a major, stand alone, breakthrough in fire and explosion protection. Therefore, this paper devote its content to presenting a level playing field approach for best informing you the consumer/end user of FireStopper® branded products.

In the International arena, the FireStopper® brand is the recipient of the highest certifications in all categories of Governmental requirements to market such as defined below:

Anti-Explosion:

Initial stage testing – Gexcon, AS (Norway)

Handheld Portable Extinguishers:

ANSI/UL711, ULC – Southwest Research Institute (San Antonio, TX)

Defense Logistics Agency (DLA) US Gov. NSN Approval #s’ EN3-7; EN3-81 – MPA, Dresden (Germany)

CE2 – DNV

Firefighting Foam Concentrates:

EN1568 – MPA Dresden ICAO – CNPP (France)

IMO – MPA Dresden, Lloyds Registry, DNV, MED CE

Environmental Testing:

NAMSA, USA

Executive Summary

Every new technology has barriers erected by the competition and industry supported organizations limiting access to the market. Often times these barriers are based on myth or inaccurate statements designed to erode credibility in favor of the status quo. Sometimes the barriers are represented to be real world experiences of customers using similar technologies.

In the case at hand, a truly new technology has arrived, that addresses the solution of serious problems in a different and novel way. In all cases, it is incumbent upon the developer of said new technology and its vendors to educate the market place, provide factually supported analysis and provide the media with the opportunity to review the technology/products on the new approach to solving problems of safety to both the environment and the consequences to humanity.

The general public, Government, industries such as the energy generating plants, oil refineries, chemical processing plants and mining operations, among many other industries, operate in the presence of combustible gases and vapors, the precursors of explosion, in addition to the presence of flammable materials such as metals and the consequential devastating fire events these conditions can manifest.

The objective of this document is to spotlight the least known and potentially most destructive danger to our species. Then, to introduce and describe the now available, solution to blocking a Fukushima type disaster from occurring, which by all publicly available information, far exceed the conditions that gave birth to such a disaster.

Background

When fuel rods in a nuclear reactor are “spent,” or no longer usable, they are removed from the reactor core and replaced with fresh fuel rods. The spent fuel rods are still highly radioactive and will continue to generate significant heat for decades. The fuel assemblies, which consist of

dozens to hundreds of fuel rods each, are moved to pools of water to cool. They are kept on racks in the pool, submerged in more than twenty feet of water, and water is continuously circulated to draw heat away from the rods and keep them at a safe temperature.

Because no permanent repository for spent fuel exists in the United States, reactor owners have kept spent fuel at the reactor sites. As the amount of spent fuel has increased, the Nuclear Regulatory Commission (NRC) has authorized many power plant owners to increase the amount in their storage pools to as much as five times what they were designed to hold. As a result, virtually all U.S. spent fuel pools have been “re-racked” to hold spent fuel assemblies at densities that approach those in reactor cores. In order to prevent the spent fuel from going critical, the spent fuel assemblies are placed in metal boxes whose walls contain neutron-absorbing boron.

However, since the 1940s’ all nuclear energy plants are suffering the expensive and seriously threatening environment of zircaloy fires, which until the advent of the FireStopper® Technology no available fire extinguisher or extinguishing agent proved capable of extinguishing said alloy flammable event. The risk of devastating fire in the fabrication process of the fuel rods, the implementation of said fuel rods within the reactor and the storing of said spent fuel rods has been a clear and present danger to all however, now the FireStopper® Extinguishers have proven, through indisputable demonstration to the Nuclear Energy Industry, that this technology’s product is clearly the only extinguishing system that provides said necessary safety devise.

Notwithstanding the above, the US DoE, Westinghouse and others within this channel of business worldwide, now have the opportunity to eliminate the fire and explosion devastating events born out of this hazard.

General Risks and Vulnerabilities

If a malfunction, a natural disaster, or a terrorist attack causes the water to leak from the pool or the cooling system to stop working, the rods will begin to heat the remaining water in the pool, eventually causing it to boil and evaporate. If the water that leaks or boils away cannot be replenished quickly enough, the water level will drop, exposing the fuel rods.

Once the fuel is uncovered, it could become hot enough to cause the metal cladding encasing the uranium fuel to rupture and catch fire, which in turn could further heat up the fuel until it suffers damage. Such an event could release large amounts of radioactive substances, such as cesium- 137, into the environment. This would start in more recently discharged spent fuel, which is hotter than fuel that has been in the pool for a longer time. A typical spent fuel pool in the United States holds several hundred tons of fuel, so if a fire were to propagate from the hotter to the colder fuel a radioactive release could be devastatingly large.

The spent fuel pools in boiling-water reactors are located only within the secondary containment of the reactor—the reactor building—and not within the more robust primary containment that is

designed to keep radiation released from the reactor vessel during an emergency event from escaping into the environment. Thus, any radiation released from a spent fuel pool is more likely to reach the outside environment than is radiation released from the reactor core. Moreover, because it is outside the primary containment, the spent fuel pool is more vulnerable than the reactor core to certain terrorist attacks like deliberate aircraft crashes.

Continuing to add spent fuel to these pools compounds this problem by increasing the amount of radioactive material that could be released into the environment. A large radiation release from a spent fuel pool could release more cesium-137 than the Chernobyl disaster, resulting in thousands of cancer deaths and hundreds of billions of dollars in decontamination costs and economic damage.

Treatment and Management of Sodium-Bonded Spent Nuclear Fuel

Sodium-bonded spent nuclear fuel contains metallic sodium that was used as a heat-transfer medium within the stainless steel cladding (outer layer) of the nuclear fuel. While sodium has been removed from the fuel’s external surface, some sodium remains bonded to the uranium metal alloy fuel within the cladding and cannot be removed without further treatment. This sodium could complicate compliance with the eventual final repository waste acceptance criteria. Metallic sodium reacts vigorously with water, producing heat, potentially explosive hydrogen gas, and sodium hydroxide, a corrosive substance. Sodium is also pyrophoric (i.e., susceptible to spontaneous ignition and continuous combustion). Most (i.e., 99 percent by weight) of the sodium bonded spent nuclear fuel contains metallic uranium and plutonium. These metals are reactive in the presence of air and moisture.

The Yucca Mountain preliminary waste acceptance criteria exclude reactive and potentially explosive materials beyond trace quantities. Additionally, some of the sodium-bonded spent nuclear fuel contains highly enriched uranium that could create criticality (that is, a self-sustained nuclear chain reaction) concerns requiring control methods.

Department of Energy (D.O.E.)

A $30-billion-a-year Government organization with about 110,000 employees; Industrial sites Across the country and the responsibility to track nuclear weapons across the globe, nuclear components, analyze capabilities and capacities, maintain and track the safety mechanisms of active plants, design, maintenance of nuclear waste, oversee the National Grid among many other high risk responsibilities.

In a series of articles, the top expert at the D.O.E. has identified 5-major risks to be present within the responsibilities of the D.O.E., of which we focus this paper on the most urgent and directly applicable to the FireStopper® Technology/Products for the solution (we are certain that the FireStopper® overall Technology has derived a series of products/systems that if implemented, shall deliver the most advanced protection and safety measures available). Moreover, once one risk is addressed with the FireStopper® appropriate solution, D.O.E. will recognize the global application of this cure to other responsibilities threatening the safety of the Nation and the planet.

Risk & Solution

When fuel rods in a nuclear reactor are “spent,” or no longer usable, they are removed from the reactor core and replaced with fresh fuel rods. The spent fuel rods are still highly radioactive and continue to generate significant heat for decades. The fuel assemblies, which consist of

dozens to hundreds of fuel rods each, are moved to pools of water to cool. They are kept on racks in the pool, submerged in more than twenty feet of water, and water is continuously circulated to draw heat away from the rods and keep them at a safe temperature.

Because no permanent repository for spent fuel exists in the United States, reactor owners have kept spent fuel at the reactor sites. As the amount of spent fuel has increased, the Nuclear Regulatory Commission (NRC) has authorized many power plant owners to increase the amount in their storage pools to as much as five times what they were designed to hold. As a result, virtually all U.S. spent fuel pools have been “re-racked” to hold spent fuel assemblies at densities that approach those in reactor cores. In order to prevent the spent fuel from going critical, the spent fuel assemblies are placed in metal boxes whose walls contain neutron-absorbing boron.

Notwithstanding, a risk of auto ignition is ever present under many unforeseen conditions. Action must be taken to ameliorate the threat.

Facilities storing sodium clad spent fuel rods have implemented Halon systems as a fire containment program (in 1994, Halon production was banned and its use was dramatically reduced, nonetheless, the Government allowed its use still through today).

It is well known that Halon does not have any cooling capability and in order to deploy in massive quantity for fire suppression in this application, it would have to be deployed under a sequestered environment for safety reasons both to human exposure and the environment. Since a main requirement in the maintenance of this volatile material is to reduce the environmental temperature as well as the material temperature, Halon is not the answer.

A second candidate proposed was the deployment of water mist systems to provide both fire suppression and cooling effect, not a good viable choice. Water is well recognized as inefficient and probably the worst overall fire suppression product. Water (H2O) in liquid form at sea level (where the pressure is 1 Atmosphere) will boil into a gas at 100 degrees Celsius, or 212 degrees Fahrenheit. It dissociates at around 2000ºC. As fuel rod temperatures increase, the gas pressure

inside the fuel rod increases and eventually can cause the cladding to balloon out and rupture. At higher temperatures (around 1800°C [approximately 3300°F]) the explosive force created by the temperature rise, produce fire environments water, in any natural form, will fails massively. Below, please see results of sodium fire experiments conducted at Sandia National Laboratories:

Fig. 1

| Test Number | Diameter of pan (in) | Height of pan (in) | Mass sodium (kg) | Base steel thickness (in) | Average peak temperature at bottom of pan (deg. C) | Thickness ratio (liquid sodium / stainless steel) |

| Pan 1 | 24 | 2 | 2.6 | 0.625 | 320 | 0.7 |

| Pan 2 | 24 | 2 | 2.6 | 0.625 | 320 | 0.7 |

| Pan 3 | 12 | 5 | 4.4 | 0.25 | 800 | 11.5 |

| Pan 4 | 8 | 7 | 1 | 0.25 | 780 | 5.9 |

| Pan 5 | 24 | 2 | 3.8 | 0.625 | 400 | 1.0 |

| Pan 6 | 24 | 2 | 4.8 | 0.625 | 480 | 1.3 |

| Pan 7 | 24 | 2 | 7.8 | 0.625 | 600 | 2.0 |

| Pan 8 | 24 | 2 | 1.6 | 0.625 | 220 | 0.4 |

| Pan 9 | 24 | 2 | 6 | 0.625 | 490 | 1.6 |

| Pan 10 | 24 | 2 | 11.6 | 0.625 | 746 | 3.0 |

| Pan 11 | 24 | 2 | 9.6 | 0.625 | 648 | 2.5 |

Sodium Pool Fire Experiments

The above chart illustrates the volatility of a controlled sodium metal fire under a controlled environment experiment. We suggest that said results confirming the vulnerability of a water mist system put to this task. Notwithstanding the above, other than what the FireStopper® Technology offers for said application, there is not another alternative available. FireStopper® offers the only reliable product to extinguish any flammable metal event with it’s applicable automated system deploying the best applicable product in its arsenal. Moreover, FireStopper® not only can provide the best available detection and deployment system, it also provides the capacity to additionally furnish the overall defense system supporting any other unpredictable fire or explosion event in any facility in need.

FireStopper® manufactures the most advanced, all stainless steel, high corrosion resistant hardware system encompassing the most advanced detection and activation system available. The FireStopper® SystemsTM of explosion or fire detects within 4-milsec and activate within less than 40-milsec. These systems are designed to fit the purpose and create the desired result with the designated liquid software most viable in efficacy to complete the task.

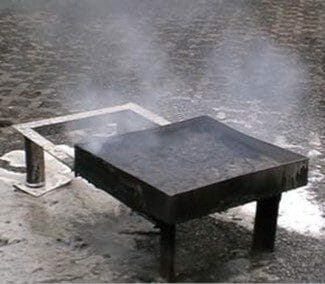

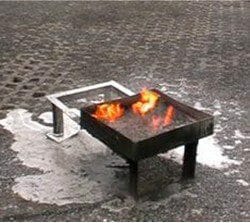

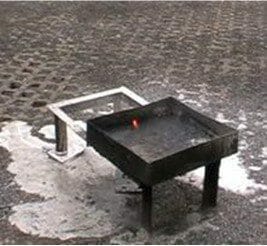

Below is a sequence of photos depicting the performance of FireStopper® PFE-FR FFC, the liquid media exclusively employed through FireStopper® Branded handheld and portable Compressed Air CatalystTM (CAC) systems. In the below sequence, we portray a factual representation of visual images and time sequence factually representing the performance of our product.

FireStopper® Certification Extinguishment of 2-Kg Sodium Metal

Fig. 2 Fig. 3

2-Kg of sodium metal – heated to auto ignition (7:45) 9-ltr extinguisher sprays on & off seq. (It took approx. 6-min to ignition) (25-sec; 6-sec; 27-sec; 22-sec; 16-sec)

Fig. 4 Fig. 5

(10:16) First phase ends – fire is out (11:34) steaming effect slows down, cooling (Surface temp. is high at this stage) is accelerating…

Fig. 6 Fig. 7

2ⁿᵈ phase: 11:35 the chemical reaction release 12:33 maximum burn off… volatile gasses ignite . as the bubbles bust

Fig. 7 Fig. 8

13:42 – Phase 2 is completed At 14:30 the extinguishment is complete (all volatile gasses are burned off)

Comments:

MPA Dresden had never seen any liquid/water-based product ever extinguished flammable metals. Obviously by the automated way in which this testing was conducted major inefficiencies were observed. Had the exercise been performed by direct application, all the product would have been applied to the subject and a more efficient extinguishment would have been accomplished.

Nonetheless, the FireStopper® performance is massively superior to all other class “D” products currently available anywhere in the world.

Zircaloy Fire & Extinguishment Demonstration

Fig. 10 Fig. 11

|  | ||

Full ignition of zirconium alloy Above 7000ºF: extinguisher is activated

Fig. 12 Fig. 13

|  | ||

FireStopper® All Fire Class Effective’s exclusive Full contact with zircaloy and extinguishment is PFE-FR FFC media display reaction with volatile accomplished. gasses and particles.

Fig. 14 Fig. 15

|  | ||

Attempt to re-ignition fails Demonstration completed

FireStopper® Extinguishers are the most advance fire protection handheld portable systems that provide the end user with never before seen or experienced safety and reliability. This new generation of portables also provides economic and ecological advantages over all other available extinguishers and in addition, for the first time, avails to the user the comfort of knowing that their health is not at risk when employing this product.

Moreover, by comparison, this generation of products are the only such product that are effective on all flammables on the planet, embody the safest fabrication of components and provide the longest warranty for reliability.

Conclusion

Because of political decisions, spent fuel in the United States will have to be stored either at reactor sites or in regional interim storage facilities. Given the political difficulties of finding a state and community willing to host either an interim storage facility or a waste repository, predictions of success or timing cannot be made. Here is what we do know:

- Storage at reactor sites will be necessary for a minimum of 10 more years.

- According to NRC, spent fuel can be safely stored in dry casks for at least 60 years, and evidence may show that it can be stored for even longer.

- Building an interim storage facility is currently not permitted by law. Therefore, legislative action will be necessary before such a storage facility can be considered.

- Once an interim facility has been identified and licensed, transportation to the site will require considerable additional time and investment.

- Until DOE removes the spent fuel from operating and decommissioned sites, the cost to taxpayers for the government’s failure to build a repository will continue to grow.

- The top priority for ending this costly financial obligation completely is to remove spent fuel from decommissioned sites. The obligation would continue for operating sites, however, until DOE removes all the spent fuel, as obligated by contracts with utilities, it is the Governments duty to implement new technologies such as the FireStopper®/EnviroSafe® Technology and their subsequent appropriate products for this industry.

Facilities throughout the world will encounter similar and possibly worst Governmental scrutiny over this very serious matter. In the meantime, any new or existing nuclear plant should consider new and effective measures to protect the functioning of the plant, the personnel and most important the environment, the general population and the planet.

This is no longer a question of economics; the responsibility lay squarely in the hands of Government and Industry to identify, test and implement novel applicable technology to deliver the most responsible safe environment for this industry.

** FireStopper International Limited is keenly focused on providing Government and industry the most advanced products its Technology has to offer. In this channel of business it does not have access to fissionable materials to test the level of efficacy its newly developed products afford this industry. Therefore, we encourage Governmental interested parties to participate in the investigation of important technology such as this. FireStopper® is committed provide limited assistance in this matter to the limits necessary to protect this very valuable trade secret technology.

_________________________________

1 This Standard refers to hardware durability, reliability and efficacy

2 This Mark assures manufacturing quality through yearly inspections